Murky Materials

The reality of the fashion industry is bleak and it’s worse than many thought possible.

November 17, 2021

It’s no secret that the fashion industry is no stranger to controversies.

Household brand names such as H&M, Urban Outfitters, and Forever 21 have been accused of designing cheap and trendy clothing intended only to last for one season.

The reality of the fashion industry is bleak. According to an article in Entrepreneur Magazine, “practically every stage in the life cycle of clothing has negative implications for our planet.”

Many factors contribute to fashion’s negative effects on the planet. However an important variable which often goes unnoticed is the materials that go into making inexpensive clothes and the plethora of problems created in their production.

One such material which is very popular among consumers is cowhide or calfskin leathers.

Tanned skins are one of the last materials that one would expect to see on this list. The tanning industry poses threats to both the environment and those that work within it.

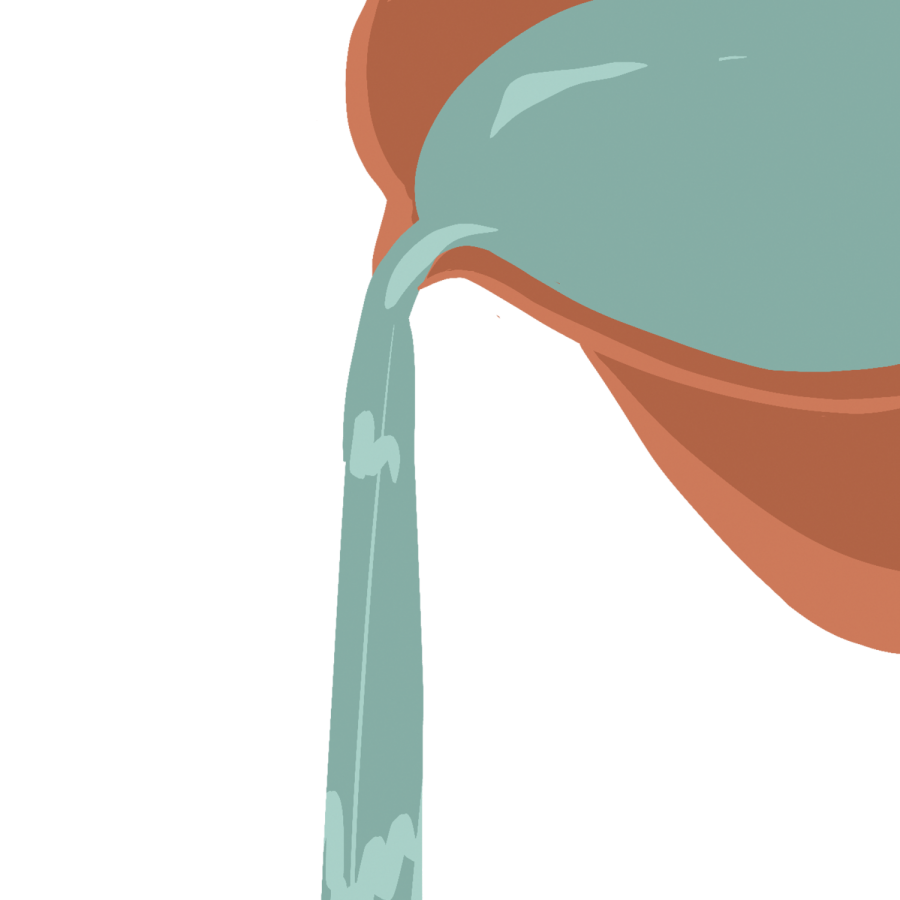

Manufacturers have managed to find “profit maximizing” production methods that come at the cost of the environment and freshwater supplies.

Leather that is tanned with chromium and/or formaldehyde, which are toxic chemical compounds, account for up to 90% of the leather available on the market today.

This is mainly because the chemically dependent tanning process can be completed in a matter of days, rather than in a matter of months.

Historically, leather has been tanned with natural “tannins” which include oak bark, leaves, vegetable extracts, and plant roots.

The process, which is known as vegetable tanning or “veg-tan”, takes many months to complete and is both costly and labor intensive.

The finished product is considered to be far better in quality, durability, and overall finish than its chrome tanned counterparts.

Chrome tanning has and will con tinue to dominate the market due to its cost effective production as it takes only a few days to complete.

Gentleman’s Gazette Magazine, pointed out that, “chrome tanning allows you to end up with leathers that are really thin, soft and flexible… chrome leather also typically holds color much better, is more colorfast and you can also have a much larger range of brighter colors.”

However, what often goes unnoticed by general consumers is the whole host of destructive effects created in the production of chrome tanned leather from water shed to workers.

Workers in charge of doing the “dirty work” in the tanneries suffer infertility, birth defects, and respiratory problems due to the chromium and/or formaldehyde found in the tanning solutions.

This toxic tanning solution has been known to melt and burn the skin off of tannery workers employed in developing countries with little to no safety regulations.

The toxic waste ends up in rivers and waterways, along with other waste created by the tanneries.

In a PBS NewsHour interview in 2017, Richard Pearhouse of Human Rights Watch said,

“Each time I would spend a period of time in [Bangladesh], I would fall sick to some of the illnesses I was witnessing with some of the people who were living there and working there,” he added, “It’s hard to overstate how polluted [the tan ning district] is.”

The climax of the matter is that even though chrome-tanned leathers are cheaper, they do not wear or patina well. Due to the finish on the leather, they can end up “cracking” after a few months of use.

Another very popular material that causes environmental problems and often goes unnoticed is cotton fabrics.

According to Environmental Club leader junior Phoebe Ray, “Cotton makes up about half of all the materials used in textiles, but the way it is grown is environmentally unsustainable.”

Throughout the many stages of cotton production and manufacturing, both the health and safety of the environment and workers have been neglected. The harmful effects of cotton production are usually felt before any seed has been planted.

To fertilize the soil for farming, farmers use chemical fertilizers to increase efficiency.

The toxic elements in the fertilizer can find their way into runoff water during storm cycles, and end up in freshwater streams which people in developing countries rely on for their drinking water.

When the fertilizer is not being eroded into streams, rivers, and lakes, it seeps into underground freshwater aquifers that supply drinking water.

When the cotton seeds are planted, the crops need to be treated with pesticides due to cotton’s naturally delicate and soft state which is normally subject to insects and pests.

These harmful pesticides are known to affect the health of farm workers and nearby populations, adding to the human cost of production.

Once the cotton has matured enough, it can be harvested by machines.

The newly harvested cotton is pressed into varying sized rectangular bales that are usually sold to processing plants.

Considering cotton is labeled as a commodity crop, there is no shortage of processing infrastructure dedicated to turning the field crop into materials that can be used in textile production.

While the processing plants themselves have changed over the years to improve efficiency, what has not changed in some plants is the chronic lack of safety concerns for the workers.

According to a safety investigation by Textile Today, it was concluded that, “Cotton in its whole processing value chain can generate potential health hazards.

From harvesting fields to ginning mills; spinning, knitting to processing mills cotton micro dust are causing chronic coughs and sometimes even bronchitis to the workers who are severely exposed to them.”

When the spinning machines begin to spin the cot ton into usable materials, toxic dust and debris fill the air exposing workers to a multitude of respiratory issues.

Once the processing has finished, the fabric is treated in vats of industrial bleach before it is dyed into appealing colors.

New York based clothing designer Angel Chang, a sustainable fashion advocate, stated in a 2017 TedX talk, “Some of these [vats of chemicals] contain cancer causing cadmium, lead, chromium, and mercury.”

When the finished material comes out of the processing factories, they find their way into sweatshops and unsafe factories.

Scientists and climate researchers agree that there is only one way to tackle the problems that come with fast fashion.

According to Kirsi Niinimäki, an associate professor at Finland’s Aalto University, “It is quite critical that we as consumers accept that these cheap garments are not possible if the environmental impacts are really all taken care of… In the future, we should produce less, we buy less and there will be less waste.”